Hollow Concrete Blocks in Saudi Arabia : Features, Uses & Benefits

Concrete masonry blocks are considered one of the most important requirements for construction companies in Saudi Arabia. In recent times, revolutionary changes in ready mix concrete manufacturing technology and material sciences have made it possible for ready-mix concrete suppliers in Saudi Arabia to produce multi-dimensional, well shaped, decorated, colored and textured blocks. Hollow concrete blocks can be used as both structural as well as non-structural constituents in various construction companies in Saudi Arabia. They are ideal building blocks in the Kingdom of Saudi Arabia.

What Are Hollow Blocks?

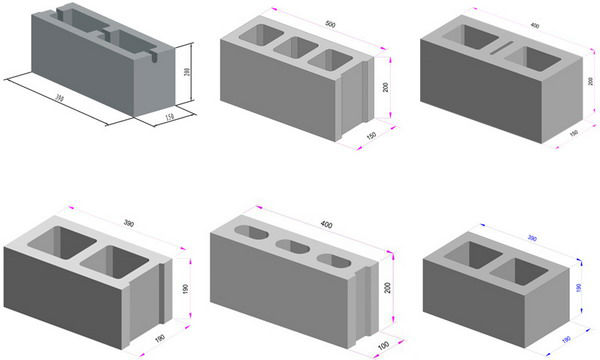

In reality, a hollow block has one or more than one hollow cores. These hollow-core concrete blocks diminish the total cross-sectional element of the block by no less than 25% while hollow-core concrete blocks are up to 50% solid. Generally, standard hollow blocks come in both half and full-sized shapes. When it comes to full-size hollow concrete blocks, they can be made available to you in rectangular shapes. The full-sized hollow blocks contain two cores. On the other hand, half-sized hollow concrete blocks can be made available to you in cubical shapes and they have one core.

There are several types of hollow blocks in Saudi Arabia like from stretcher blocks to corner blocks, pillar blocks to jamb blocks, partition blocks to lintel blocks and frogged brick blocks to bull nose concrete blocks. These types of hollow concrete blocks are made in perfect size and shape by ready mix concrete companies in Saudi Arabia. The Hollow Block 12" (200 X 300 X 400) is up to 32kg in weight whereas Hollow Block 10" (200 X 250 X 400) is about 31kg in weight. The Hollow Block 8" (200 X 200 X 400) contains 23kg weight while Hollow Block 6" (200 X 150 X 400) holds 18kg weight. The Hollow Block 4" (200 X 100 X 400) has weight up to 14kg whereas Hollow Block 8" (200 X 200 X 400) has weight equal to 27kg.

Features of Hollow Concrete Blocks

- ·Hollow concrete bricks or blocks are typically made from a chemical admixture of Portland cement, mingled cement, different varieties of aggregates, crushed stones and water.

- ·They are also known concrete masonry units (CMU) in Saudi Arabia.

- ·Hollow blocks are lightweight, affordable, immensely durable and fireproof product in KSA.

- ·It is very easy to install hollow blocks at job site.

- ·They have low maintenance cost.

- ·Hollow concrete blocks can be decorated in the most splendid fashion at various structures like foundation walls, fences, public barriers, etc.

- ·These blocks can be made available to you in fully solid and hollow shapes, along with two or three cores for such stretcher bricks. The standard concrete hollow blocks can be also made available to you on your request. However you should consult the ready mix concrete supplier in Jeddah to determine the size.

- ·They have flat or flanged ends.

- ·They have compressive strength and fire resistance element to increase the lifespan of each hollow block.

- ·The manufactured aggregate substances contain expanded shale, slate or clay.

How Hollow Blocks Are Made

Hollow concrete blocks are essentially used as a building material in the construction barriers, fences, walls, hedges and other surfaces. Therefore, it can be said that hollow blocks are concrete masonry unit (CMU) and such types of concrete blocks are really useful product for Saudi construction companies or real estate service providers in the country. The term precast is often used for hollow block which means that these blocks are made and hardened before they are installed at the construction sites. As most of hollow concrete blocks have one or more than one hollow space, their surfaces may be cast flat or with a creative design.

When it comes to the use, most hollow blocks are fastened one at a time and held in conjunction with spanking new concrete mortar to create the ideal length and height of the wall. Different types of materials are used while producing hollow concrete blocks in ready mix concrete factory in Saudi Arabia, including aggregates, sand, gravel, Portland cement, crushed stone. The manufacturing process goes through mixing, molding, curing, cubing and quality control. As a result, a high quality hollow blocks production is guaranteed in Saudi ready mix concrete factory. The Vibrocompression technique is employed to determine the hollow blocks quality and durability.

Uses of Hollow Concrete Blocks

There are many uses of hollow blocks in Saudi Arabia for both the construction industry as well as homeowners. Generally speaking, these types of ready-mixed concrete blocks are installed at large structures for example boundary walls, fences, hedges, foundation walls, partition walls, exterior walls, basement walls and barriers. A great thing is that a decreased quantity of concrete substance is used to make hollow blocks in ready mix concrete factory that adds up to your enormous savings in cost for the chemical admixtures for the whole structure. Coating is usually applied on hollow concrete blocks in an attempt to prevent water penetration.

From Portland cement paint to latex paint, from oil and rubber coatings to epoxy coating and from alkyd paint to urethanes, silicone is applied on hollow blocks to make them water resistant. In addition, ultraviolet rays might also be considered to improve their look. These blocks are readily available in light weight so you can easily lift them for rapid installation. The hollow cores provide a great edge for builders to install the reinforcing materials like steel bars if the design requires reinforcing. Often water pipes are carried through them. These are fully solid blocks which can be used for paving different structures and other infrastructures in Saudi Arabia where holes would be hazardous or uncomfortable.

Key Benefits of Hollow Concrete Blocks

Hollow bricks are frequently used in Saudi Arabia to construct both the load-bearing and non-load bearing walls, depending on the compressive strengths of chemical admixtures used. Some of the great advantages to use hollow blocks are:

Eco-friendly – Hollow blocks in Saudi Arabia are green living product because they are made from recycled, waste materials and natural substances, including rice husk, granite slurry, fly ash, coal ash, crushed stone and other materials.

Energy Preservation – Hollow bricks in Saudi Arabia are used to minimize the usage of both cooling as well as heating devices as per your seasonal needs thanks to their thermal insulation property. This decreases your energy consumption. Hence it saves your energy resources and pockets.

Improved Usage and Strength – Hollow concrete blocks provide a great compressive strength and that is why it becomes very easy for builders to install your ready mix concrete hollow blocks on heavy wall compartments, geysers, cabinets, foundation walls, fences and other surfaces. The presence of hollow cores makes it easy for builders to surpass the electrical and plumbing fixtures as compared to solid blocks where you need to form toting up your labor, damage and cost.

Thermal & Sound Insulation

These types of ready mix concrete blocks have thermal insulators to pass air through hollow area of these blocks. The interior structure of these hollow bricks will remain cool in summer and warm in winter seasons particular the clay hollow blocks. Thus, hollow bricks offer more sound insulation as compared to solid concrete blocks.

Cost-effective & Low Maintenance

Hollow concrete blocks in Saudi Arabia are very cost-effective as compared to solid concrete blocks. This reduces the overall structural cost for real estate companies in Saudi Arabia. It improves the performance of masons in ready mix concrete and construction companies. In addition, it cuts man hours and hence further decreasing labor costs. Using hollow concrete bricks also reduces installation costs. Less mortar is needed because the hollow blocks are available in large size. It also reduces your energy consumption hence increasing the lifespan of your edifices.

Fast Execution of Work

Hollow blocks are available in equal sizes, shapes, weight and styles to fulfill your requirement at ease. Therefore, installing these blocks is easy for builders as it ensures the fastest execution of work at construction site.

Impeccable Durability

These blocks are compressed by high pressure and vibration in concrete factory hence making them impeccably durable and enormously hardened to bear severe load or weight.

Preserves Space

The creation of thin wall structures with hollow concrete blocks is nowadays a prevailing trend in Saudi Arabia. Therefore, it helps to conserve space used in construction process and it also decorates your floor area.

Bonding of Mortar and Plaster

As the exteriors of hollow concrete bricks are uneven, this creates an improved bonding between mortar and plaster. To get more information about ready mix concrete and hollow concrete blocks in Saudi Arabia.